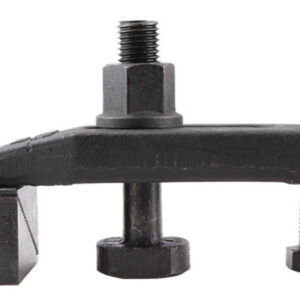

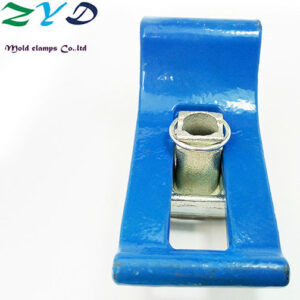

ZHUSHI mould clamp

Use of high-speed mold clamps and precautions

Clamping workpieces with parallel high-speed mold clamps is a common method on milling machines, especially on horizontal milling machines, where end milling cutters are often used for milling. When installing workpieces with parallel high-speed mold clamps on a milling machine, the tools used by the machine tool are relatively simple, mainly including machine high-speed mold clamps, horns, T-bolts or T-nuts, etc…

To meet the needs of installing workpieces of different shapes, the shape of the pressing plate is also made into many kinds. Pay attention to when using the high-speed mold clamps:

(1) The position of the pressing plate should be arranged properly, and it should be pressed on the machining center with good rigidity of the workpiece, and the clamping force should be appropriate, otherwise the workpiece with poor rigidity is easy to deform.

(2) The machine bed iron must be placed under the high-speed mold clamps correctly, and the height must be the same as the workpiece or slightly higher than the workpiece, otherwise, the compression effect will be reduced.

(3) The high-speed mold clamp bolt must be as close to the workpiece as possible, and the distance between the bolt and the workpiece should be less than the distance between the bolt and the shim so that the pressing force can be increased.

(4) The bolts must be tightened, otherwise, the workpiece will move due to insufficient pressure in the machining center, which will damage the workpiece, machine tool, and tool.

Reviews

There are no reviews yet.