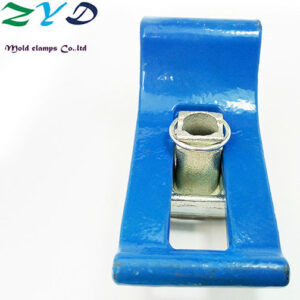

mold clamp m16

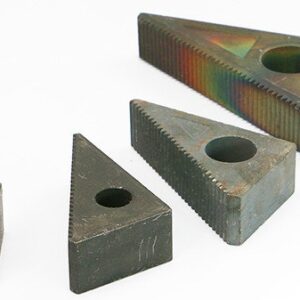

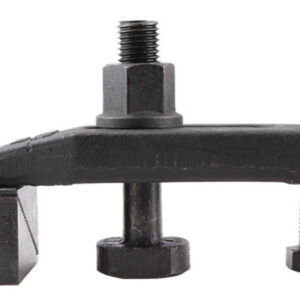

The manufacturing process of the die pressing plate: It is made of 45# medium carbon steel as a whole.

After high temperature heating and hammer hammering, its own hardness can reach a hardness of more than 30HRC. Then use a universal milling machine to process the plane and long grooves to achieve a surface finish of 3.2. As well as the parallelism and flatness of the platen, all errors are not more than 0.02MM. After heat treatment and quenching, it reaches 35HRC to 40HRC required by JB. Finally, the surface is blackened or blued to achieve the purpose of preventing rust spots.

Reviews

There are no reviews yet.