Mould Clamp With Slot

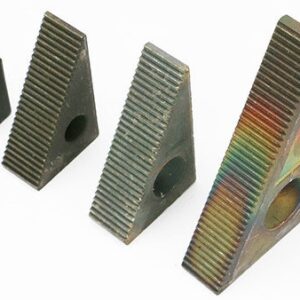

The die mold clamp is composed entirely of 45# medium carbon steel. Its hardness can reach above 30HRC after high-temperature heating and hammering.

Then, to achieve a surface polish of 3.2, use a universal milling machine to process the plane and long grooves. All errors, including parallelism and flatness of the platen, are less than 0.02MM.

It reaches the 35HRC to 40HRC required by JB after heat treatment and quenching. Finally, the surface is darkened or blued to prevent rust stains from forming.

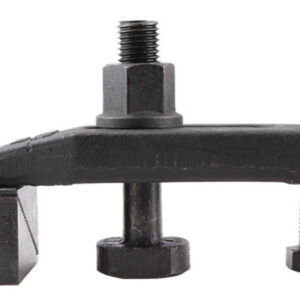

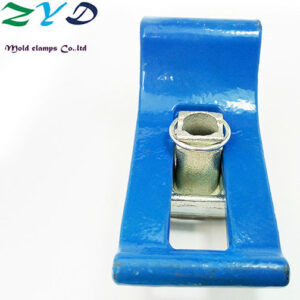

U-shaped press plates, parallel press plates, mechanical press plates, T-slot press plates, spring steel parallel press plates, bird-shaped press plates, circular press plates, fine-tuning press plates, and wide-head press plates are some of the types of mold clamps available.

The mold pressing plate is a common auxiliary component in the mold-making process. Its major purpose is to ensure that the workpiece does not vibrate or shift throughout the operation. To ensure that the molded workpiece is accurate and has a good finish. As a result, the quality of the mold pressing plate has a direct impact on the mold’s product quality. As a result, the mold platen is extremely important in the mold-making process. The die plate is strong in strength, small in size, flexible, and easy to use.

Warm and considerate service, as well as products.

Various pressure plates, big castings, machine tool castings, mechanical castings, continuous casting machine arc prototypes, molds, and inspection tools are among our factory’s primary products.

Reviews

There are no reviews yet.