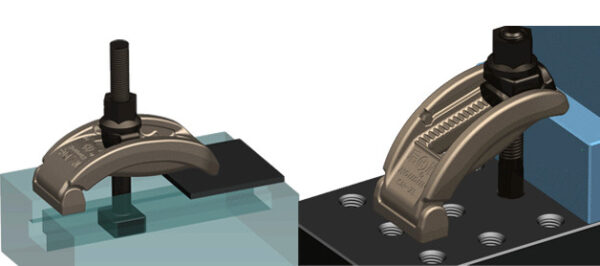

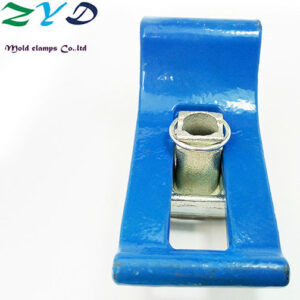

Universal Mould Clamp

hese mold clamps are designed using advanced technology with dimensionally accurate, resistant to corrosion and better durability standards.

Easy to install, these clamps are available in varied sizes and

specifications as required by the clients.

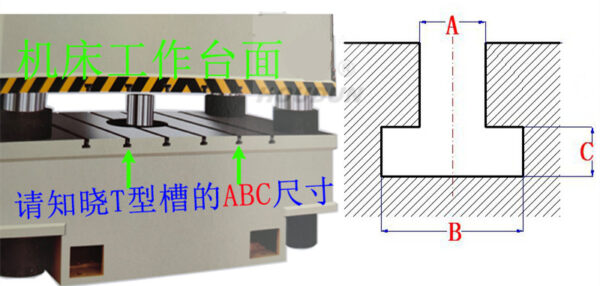

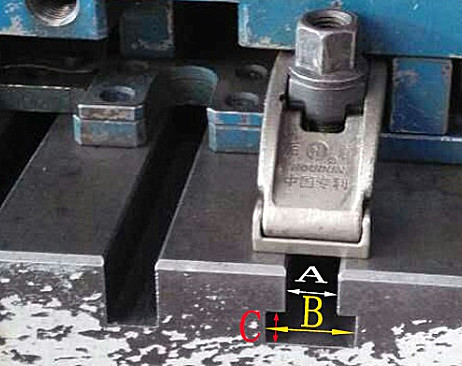

Then refer to the national standard as shown in the figure below to select the bolt that matches the T-slot (eg: M12/M16/M20/M24/M30).

You can choose or purchase bolts of other lengths according to actual needs. Please contact us before purchasing so that you can choose a more suitable model. We can help you calculate the shipping cost.

ZYD Mould Clamp is designed specially for low height applications only such as clamping of moulds on plastic injection moulding

machines and pressure die casting machines.

The compact front portion of the clamp enables it to penetrate into the limited clamping area of the mould and clamp it.

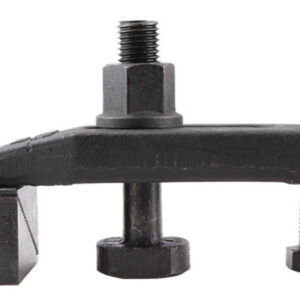

The positioning of forged swival washer on required curved groove enables the operator to set the center distance between the clamping portion and the clamping bolt as per the nearest tapped hole available on platen (where there are no T-slots).

No supports are required at the rear of the clamp as the rear portion rests on the platen and front holds the mould.?

Flanged nut is tightened on the swival washerwhich takes care of the positioning of clamp body.

These clamps are equally useful on pressure die casting machines, hydraulic presses and power presses where low height clamping is done.

Clamps are supplied complete with swival washer, flanged nut & clamping stud or T-Bolt.

Reviews

There are no reviews yet.