Mold clamping

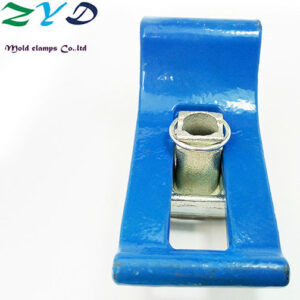

We Offer Replacement PartsIndividual mold clamp bodies

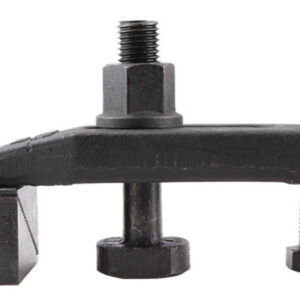

Extra large adjusting screw assemblies

Hex head adjusting screws

High strength, Grade 5, Hex head clamping screws

High strength, T-slot bolts

Heavy duty hex nuts for T-slot bolts

Round mold washers

Extra large round mold washers

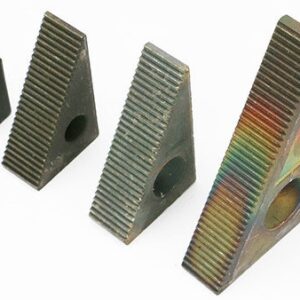

Extra large no-twist rectangular washers

Mold Clamping Tips

Place the clamping bolt as close to the mold to obtain the maximum mold holding pressure, adjust the clamp to parallel, meaning in a straight parallel line with platen and mold slot and not at an angle.

Clamps must be set parallel to the press which is critical for equal clamping of the entire mold. The proper set-up, adequate number of clamps, and the correct size of clamps in relation to mold size will ensure safer and better mold-set up and decreased production downtime.

Injection Molding Safety

Historically the injuries from injection molding machines have included crushing during the cycle of the machine, burns, slips, trips, and falls due to oil or plastic pellets on the walking surfaces. There are reported deaths as a result of mold falling off the platen Injection molding products are based in China’s manufacturing industry due to their extensive use in life. The production of injection molding products requires very high injection molds. The article explores three major aspects of injection mold assembly, mold trial, and maintenance, and finds injection molds The best method for assembly. The size and other items must be checked before the injection mold is installed. The assembly benchmark must be determined first, the main parts are assembled, and then the screws and the pressure plate are used to install and fix the injection mold. The injection mold is installed on the injection molding machine. The raw materials and process parameters used at the time should be the same as those of batch production. If the product is found to be unqualified during the mold trial, the cause should be found out in time and corrected. In addition, the article also discusses the normal wear or abnormality of the mold during use The normal damage was studied, and the corresponding maintenance methods were put forward in order to improve the product quality of injection molded products.

Reviews

There are no reviews yet.